With more than 70 years of experience ZERMA is one of the leading producers of high quality size reduction technology, covering the whole spectrum of size reduction starting with the GSL series.

The slow speed granulators of the GSL series are designed to recycle rejects and scrap in injection and blow molding applications. Various hopper and discharge designs allow a flexible and customised implementation of the machines.

GSL 180 Mainly used in injection and blow molding processes as beside the press machines to grind runners and sprues

GSL 300 Can be used as low noise central granulators for small throughput requirements as well

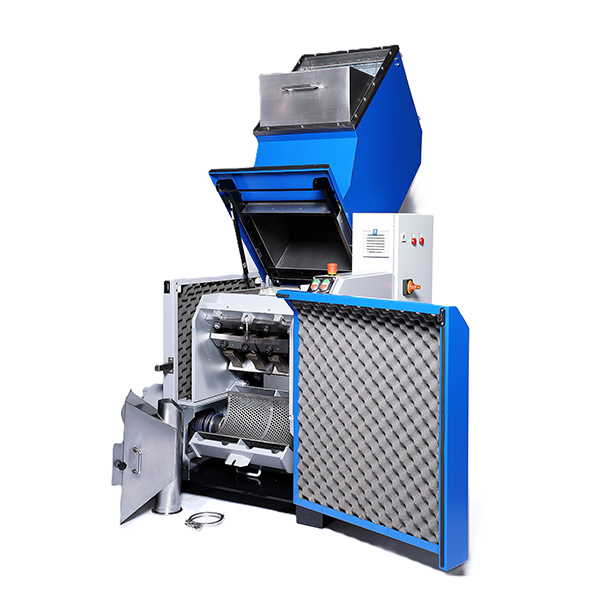

The slow-speed granulators of the GSL series operate at a low rotor rpm ensuring a minimal noise level and the highest quality virtually dust free regrind. The specially designed rotor knives can be resharpened several times and due to their unique design do not require any adjustment when installing in the granulator after sharpening. The material to be processed is introduced into the machine via a light-weight sound dampening hopper built in sandwich construction. The screen mounted at the bottom of the cutting chamber regulates the final size of the granulated material.

The regrind is collected in a stainless steel bin, which can be emptied with normal vacuum systems.

All machines are designed according to latest statutory safety standards to avoid operation while the cutting chamber is accessible.

Easy maintenance and cleaningAccess to the cutting chamber and screen is quick and easy without the need for tools. Seals and high precision manufacturing ensure a clean machine environment.

The rotor is equipped with specially designed knives. The curvature of the knives ensures a constant cutting gap even after sharpening without the need to readjust the rotor knives.

The rotor shaft is supported on both ends by heavy duty bearings. Due to the modular design of the rotor the shaft is sized for the widest machine ensuring performance and longevity across the whole range. The staggered design of the rotor means that a maximum of 2 blades cut at any one time thus reducing the stress on the rotor.

All GSL granulators are equipped with lightweight sound dampening hoppers featuring sandwich construction of a thick layer of sound dampening material between the inner stainless steel and external aluminium. The standard hoppers allow feeding by hand or robot.

The proven ZERMA quick-snap system allows a quick and easy opening of the machine and removal of the front plate to gain access to the screen. This allows simple cleaning when changing colour or material. Safety switches avoid starting of the machine when the cutting chamber or rotor are exposed.

Optionally the GSL granulators can be equipped with complete sound proofing cabin and doors to further reduce the operational noise.

The slow speed granulators of the GSL 180 series feature a closed 180 mm diameter rotor with width range options from 120 mm to 430 mm. The rotors are comprised of single discs arranged on an oversized drive shaft connected to the gear motor. This allows for efficient and low maintenance power transmission. The material can be fed manually, by conveyor or by robot into the large sound dampening hopper. Typically the machines are placed on a low frame with integrated heavy duty casters. Discharge of the material is accomplished via vacuum system from the integrated stainless steel material collection bin.

The slow speed granulators in the GSL 180 series are specifically designed for the processing of runners, sprues and rejects in injection molding processes. The safe, easy access to the cutting chamber allows for quick changeovers in case of material or colour changes. The low rotor speed allows processing of pliable as well as rigid materials and ensures high quality regrind with low dust.

The slow speed granulators in the 300 series feature a 300 mm diameter rotor with widths ranging from 400 mm - 800 mm. The rotor is directly driven by a geared motor. This ensures smooth operation even when processing challenging materials. The low rotor speed generates less noise and a high quality, low dust regrind. The specifically designed rotor knives can be sharpened multiple times and can be installed in the machine without readjustment of the cutting system.

The Quick-Snap system and large knobs allow fast and easy access to the cutting chamber without the need for tools. The material is introduced into the machine via a sound dampening hopper. The machines can be customised depending on the application with different hoppers and discharge options.

ApplicationsThe slow speed GSL300 series are well suited for the processing of production scrap as well as voluminous parts. They can also be used as central granulator for low volume production or in laboratory environments. The sturdy construction and high torque of the GSL300 series allows processing of heavier, thick walled and other challenging materials.

In a comprehensive redesign, the best features from the proven GST serie have been integrated, with particular emphasis on weight, size, handling, and energy efficiency. These compact granulators are equipped with complete sound insulation, resulting in an extremely quiet operation. The granulators are available with a rotor diameter of 250 mm and widths of 300, 450, and 600 mm. As with all ZERMA granulators, rotor and stator knives are adjustable outside the machine to reduce maintenance downtime.

The strongly curved, tangential back wall of the cutting chamber, combined with the aggressive open rotor design, ensures reliable material infeed and minimises the risk of bridging in the hopper.

ApplicationsThe compact granulators are ideal for use in blow moulding operations. Due to their low infeed height these machines are easily loaded with material manually or using a small infeed conveyor. The low noise emission and compact footprint make this granulator range a perfect solution for inline recycling applications.

In a comprehensive redesign, the best features from the proven GST series have been integrated, with particular emphasis on weight, size, handling, and energy efficiency.

Check out our latest video about the GST series:

Visit us at the PLASTICS & RUBBER THAILAND 2024 exhibition in Bangkok, Thailand! As ZERMA Machinery Thailand, we proudly present our new product range the GST granulators and our GSL slow speed granulators.

Date: May 15-18, 2024

Location: BITEC, Bangkok

Our team looks forward to introducing you to our state-of-the-art slow speed granulators. Come by and find out how our solutions can optimize your production processes.

We are looking forward to your visit!

We would like to thank you for visiting us at the official opening of ZERMA Machinery Thailand. It was our great pleasure to have you as part of our celebrations.

Your interest in our products and services is of great importance to us and we are proud to present you with innovative solutions for the plastics and rubber industry.

We value your trust in ZERMA Machinery Thailand and look forward to continuing our cooperation in the future. Don't hesitate to contact us with any questions or concerns. We are always ready to help you.

Thank you again for your visit. We look forward to having more opportunities to work together in the future.

450 Sukhumvit Road, Tambon Huaypong, Amphur Muang Rayong,

Rayong 21150, Thailand

Phone: +66 3301 3589

sales@zerma.co.th

Buchenring 8 - 10

21272 Egestorf (Germany)

Phone: +49 4175 3739969

info@zerma-europe.eu

beistellmuehle.de

For UK: Summit Sytems Ltd.

Tame Park Wilnecote

Tamworth Stafforshire

B77 5DY England

Phone: +44 1828 265 800

info@summitsystems.co.uk

www.summitsystems.co.uk

We are looking forward to helping you with your application or question.